NEVA under the magnifying glass: our supplier of ZEBR rolling machines. Partnership that has grown into friendship

The Czech engineering company ZEBR is today the most important manufacturer of machines for the production of blinds not only in Europe. We have been working together since 1999, when the first machine for the production of external blinds was developed with our participation.

What is a rolling mill?

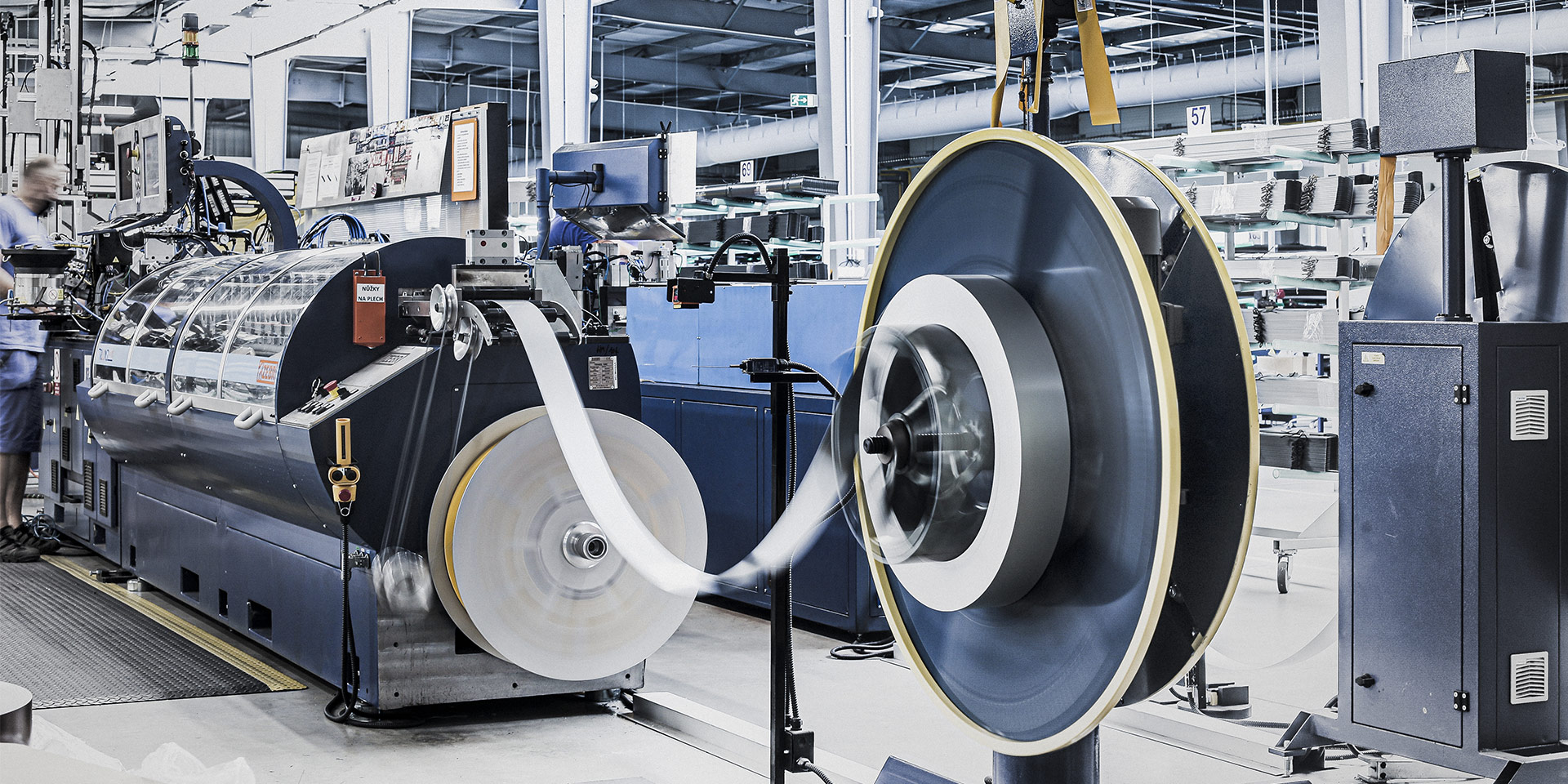

A rolling machine with accessories, also called a rolling mill, creates a finished package of blinds from a lamella scroll. The lamella scroll is fed into the machine on one side and moves through the rolling wheels and individual tools to the other side and the assembly section, where the machine operator removes the finished slats. The following slat parameters are monitored:

- rolling of the profile to the required shape and values,

- rolling of the sealing rubber into the lamella scroll,

- quality of the cut-through holes on lift tape,

- installation of hooks for stringing the ladder,

- riveting of guide pins.

The rolling process finishes in tying, i.e. connecting the shot hook with the eye of the textile ladder. The finished packet is then moved by the manipulator arms into the finished packet storage bin.

Optimization and the pursuit of continuous improvement of the production process led us to create a fully automated rolling line. The dimensions and type of external blinds, along with the unique order number, are uploaded directly from the ordering system, i.e. from the customer, to the machine. The machine control mechanisms ensure that the slats are rolled out with an accuracy of a millimetre.

But many operations still cannot be done without human hands. One important task of the operator is to feed the lamella scroll of the correct colour into the feeder as ordered. The operator also adds the necessary components to the machine (ladder, hooks, pins), keeps the machine running, and solves minor errors. Continuous tests are carried out to check the flatness and strength of the attached components. These regular checks prevent unnecessary wastage of material, enabling us to reduce the final price of the blinds.

The rolling mill operator checks that the blinds package is in order, marks it with the order number and hands it over to colleagues for assembly. This is followed by a testing phase, careful packing and dispatch to the customer.

Who is ZEBR

ZEBR is a family company based in Milovice, Moravia. It was founded in 1991 by František Zelinka, who, along with his wife and son, is still the owner today. At first they produced cutting and pressing tools, later rolling machines for internal blinds. In their own press shop, they produce sheet metal parts for blinds, technical plastic extrusions and roll aluminium profiles for insect screens. For more than 30 years, the company has developed into a world leader in the design of machines for the production of internal and external blinds. The company exports its machines to more than 30 countries worldwide, mainly to the European Union.

The first rolling line for external blinds was produced by ZEBR for us

When we decided to manufacture our own external window blinds in 1999, we started looking for a partner to help us. We were impressed with ZEBR based on their positive reviews and personal approach, so we approached them even though they were only producing machines for internal blinds.

No project is too big for Mr. Zelinka, so together we started to produce the first machine for the production of external blinds of the Z‑90 type.

We currently have 10 tracks on 6 rolling machines in NEVA

All of our machines are custom made, making our external blinds unique. Although a non-specialist cannot see the difference between blinds from individual manufacturers, much of the quality lies in the details that set us apart — high machine performance, reliability, automation, support for paperless production, etc. are also important. At ZEBR, we specify the parameters according to which we build our machines.

“The advantage of long-term cooperation is that we know the standard possibilities that the manufacturer can meet and where its current limits are. By communicating more frequently with ZEBR representatives, we can also check what new things they have introduced and what innovations they are working on. We are constantly upgrading or replacing machines with more powerful ones,” says Ladislav Vrána, one of the founders and owners of NEVA.

Our partners at ZEBR also provide remote support and continuously evaluate productivity and downtime to keep us moving towards greater automation.

Four of our machines are single-purpose machines, so they are used for the production of a specific type of slats and can, therefore, be as efficient as possible. On two of the machines, the tracks are set out like a “triangle” — that means three tracks which we can operatively change according to the current demand. For example, if one of the single-purpose machines is being serviced, production can run continuously on one of the universal machines.

In total, we roll 6 types of external blinds and one profile:

We regard our cooperation with ZEBR as friendship after 25 years

“Not only the management, but also the employees of both companies personally know each other well, so we agree on most tasks. This applies to both urgent service interventions and planned services. Further, ZEBR is based in Moravia, so we can meet very quickly,” Vrána praises the cooperation. “We are very happy that this cooperation continues after management at ZEBR was handed down from father to son,” he adds.

And what does ZEBR say about the cooperation? “NEVA is a strategic partner to ZEBR — it is a very demanding customer that takes price in quality. Every order is proof to us that the possibilities in the production of rolling lines and their automation have not been completely exhausted yet,” said Lucie Krejzová, ZEBR sales representative.