We newly use a 3D printer in the production of blinds

We continuously improve the production of our blinds and we also use new digital technologies in the process. The latest addition to our production plant is the 3D printer, which is especially helpful in the printing of product prototypes.

We already have previous experience with new digital technologies – we use the parametric 3D modelling software Autodesk Inventor for the design of products. We use it to create designs with various views, cross-sections and details, and we also determine whether the product components collide.

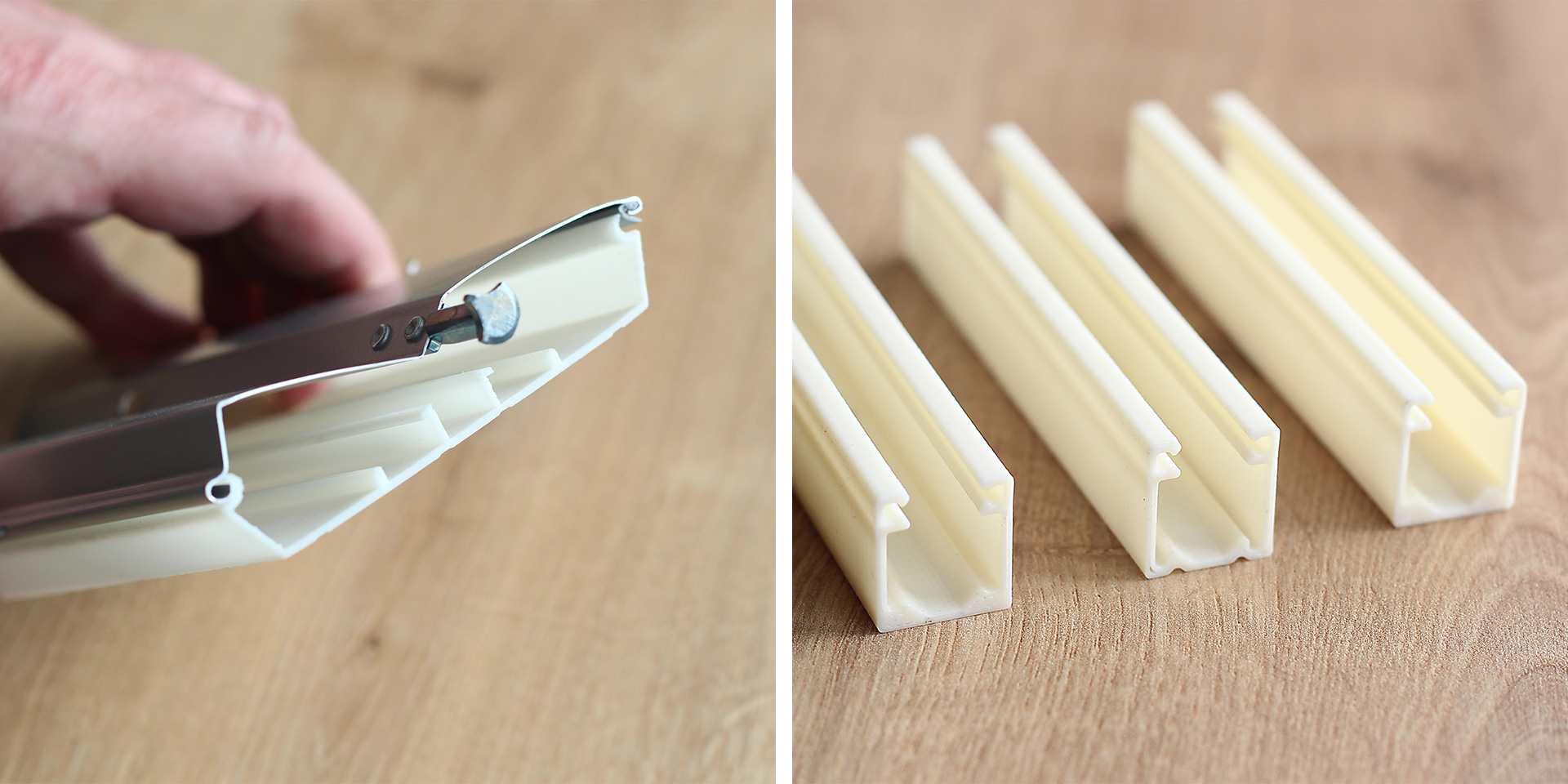

We have now moved production even further ahead. We use 3D printing to materialize these designs into functional 3D models and to test them. When we find that it is necessary to repair something, we needn’t wait for the delivery of the required part. We correct everything, edit and print it again within a few hours. Thanks to this, production is much faster and effective.

The 3D printer helps us print small series of final products and print various manufacturing aids.

In addition to functional prototypes, we also use the 3D printer to print individual components and aids that we use in the production of the blinds.