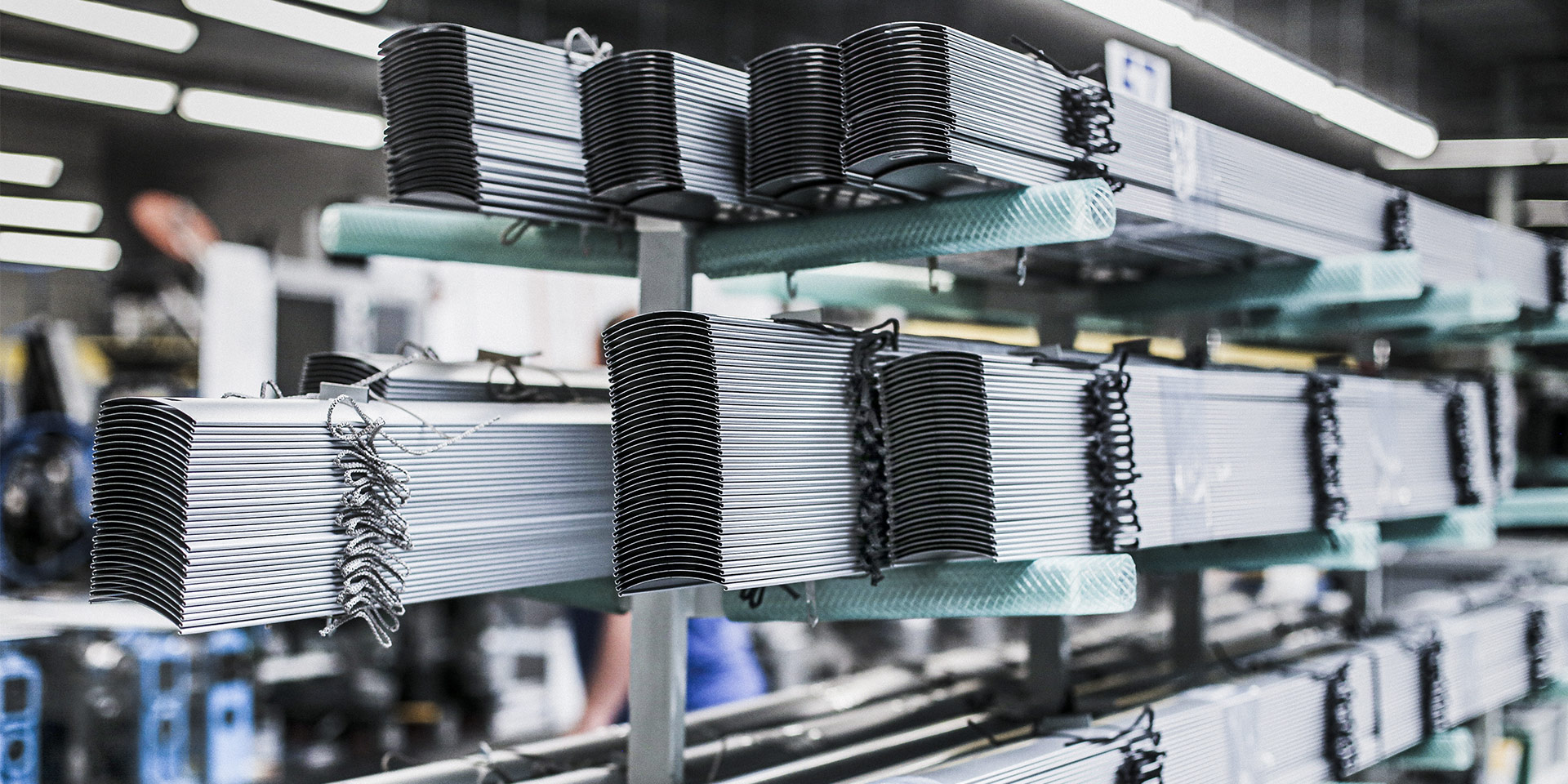

The durability of external blinds is mainly influenced by the quality of components and assembly.

External blinds have a lifespan of at least ten years or more, but it depends a lot on what components they are made of and how you as the owner take care of them. In this article, we’ll reveal everything that blinds can withstand and which components have the biggest impact on their lifespan.

External blinds are generally made of high quality materials because they have to withstand wind, rain, snow, scorching sun or, in the case of coastal areas, extremely salty air. Their lifespan is usually projected to decades

Their lifetime is even regulated by a technical standard, according to which the most durable blinds must be able to withstand at least 10,000 cycles of being pulled up and down. The standard assumes that the slats are pulled up and down twice a day on average – in which case the blinds must last at least 13.5 years.

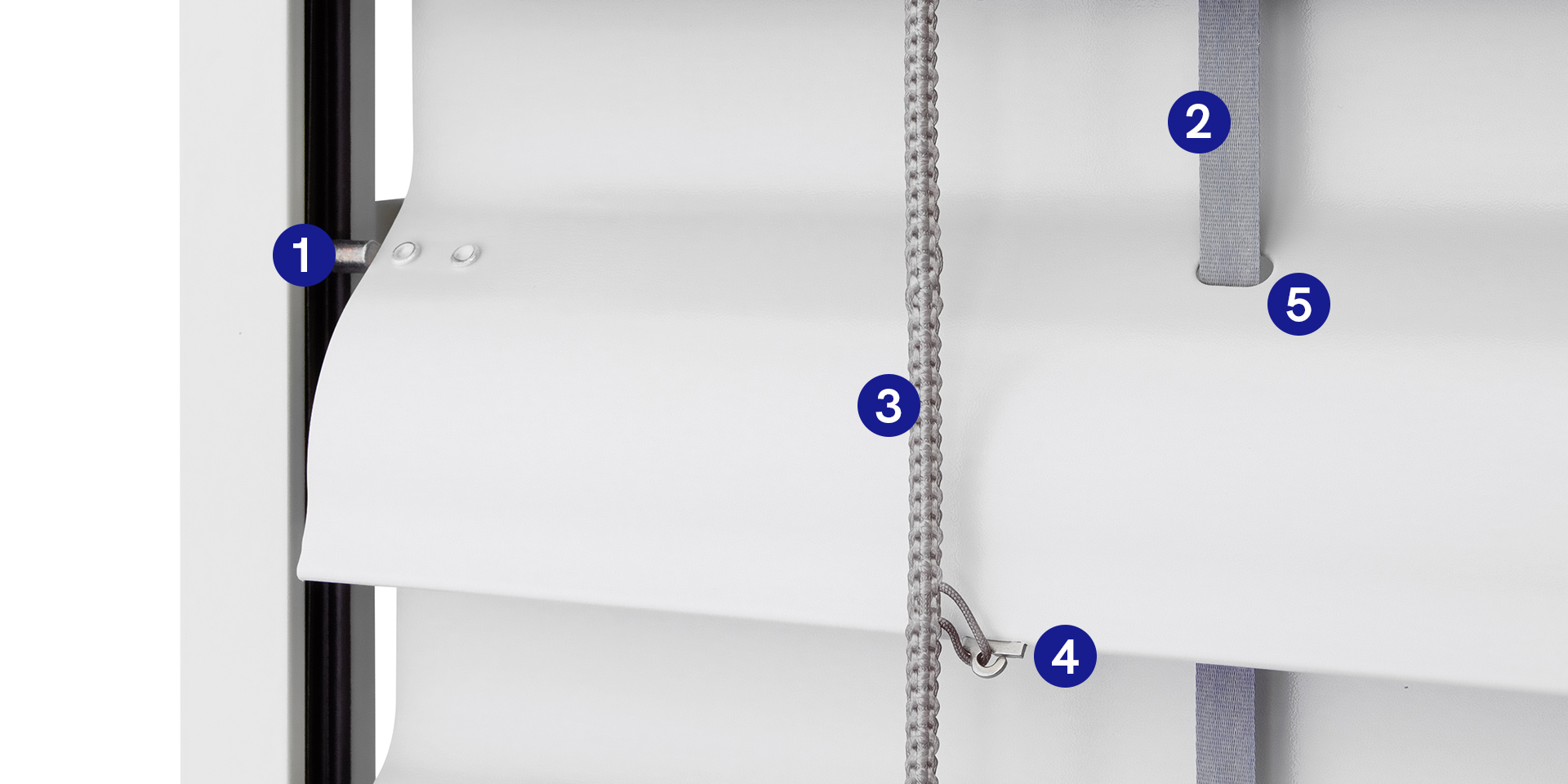

Critical elements include the lift tape and the rolled-in seal at the edge of the slats.

Let’s now delve deeper into the design of the product. Although external blinds are dominated by robust slats, it is the small, often inconspicuous components that have a much greater impact on durability. Particularly critical components include

- guiding pins,

- the ladder used to support and tilt the slats,

- metal ladder connections,

- the lift tape that lowers and pulls up the blinds,

- the hole in which the lift tape moves,

- the material of the rolled-in seal on the edge of the slats

- and the quality of the motors.

Metal guiding pins or ladder connections last longer than plastic ones and significantly increase the wind resistance of the blinds. They are also more resistant to sudden changes in temperature and you don’t have to worry about them snapping.

The lift tape also faces high stresses. It runs through all the slats, holds the bottom profile and the entire weight of the packet hangs on it. It is therefore a good idea to round the pass-through holes for the tape in the slats or pad them out so that the tape does not cut against them unnecessarily.

At NEVA, for example, we use a durable, extra wide (8 mm) lift tape and a Kevlar-reinforced ladder for this reason.

It is also important to have rolled-in rubber sealing at the edges of the slats, which must be UV-resistant. Lower quality materials will start to harden and crack after three to four years and eventually cracks or gaps form that let light through.

Ask for motors with longer warranties

Most customers order external blinds with motorised operation. Although motors offer great convenience, it is important to remember that they are one of the most common causes of complaints about blinds systems.

A good guide for choosing a solid motor is the warranty period; we recommend at least a five-year warranty, which is offered by companies such as Somfy, Geiger and Elero, with whom we have the best experience.

On the other hand, we do not recommend cheap motors (most often from Romanian or Chinese manufacturers), as their reliability is low and thus most manufacturers of blinds do not offer them.

Installation, service and care

Installation also has a huge impact on the life of the blinds. The installation of external blinds is a complicated matter in which both millimetres and the experience of the installer are big factors. Therefore, we never recommend you install them yourself and always refer you to tried-and-true proven installation companies. In our experience, most failures of external blinds are caused by unprofessional installation and, for example, with NEVA blinds, you even void the warranty if you install them yourself.

Don’t forget to look after your blinds too — clean them regularly and have them professionally serviced. We’ve expanded on taking care of blinds in this article.

When it comes to taking care of your blinds, it’s also important not to expose them to unnecessary risks, especially strong winds. Even though external blinds up to one metre wide can withstand wind speeds of up to 88 kph, this value decreases as the dimensions increase. It is therefore better to retract the blindsduring strong wind so that they are not damaged. If you fit them with wind sensors, they will be pulled up automatically in strong winds.

Technological obsolescence may be a limitation

The lifespan of external blinds may not only be limited by their physical condition, but also by their technological obsolescence. For example, motors have more and more features and smart homes looked very different fifteen years ago than they do today. As a result, some customers may feel that external blinds are ripe for replacement because they have become technologicallyobsolete.

However, replacing older types of blinds with wired controls and motors without smart functions with modern blinds integrated into a smart home is often complicated and therefore always assessed individually.

However, if the biggest problem with your external blinds is that they are no longer modern enough, it is also the best proof of their quality, durability and longevity.